Multiple Options

Multiple design options can be created based on the system requirements and constraints. Consideration is given to the drive mechanism, speed / load, drive torque, contact fatigue, pressure pulsation and volumetric efficiency. These are then discussed with the client to arrive at the best practical solution for the application.

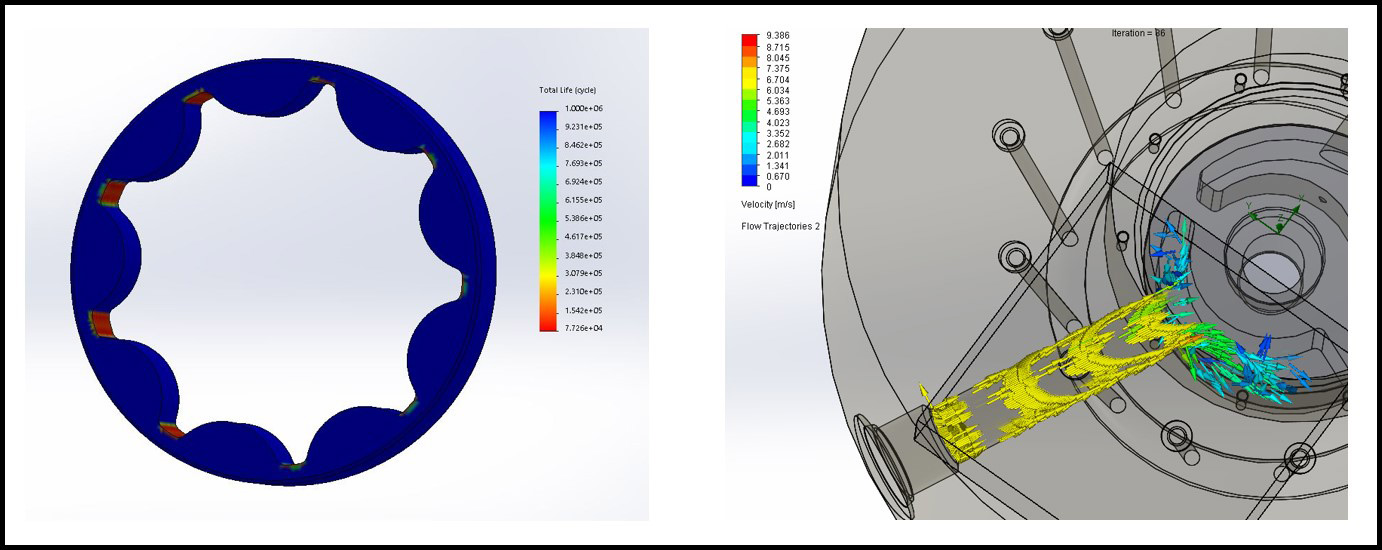

CFD & FE

CFD and FE Analysis can be undertaken to investigate system performance problems or potential wear issues.

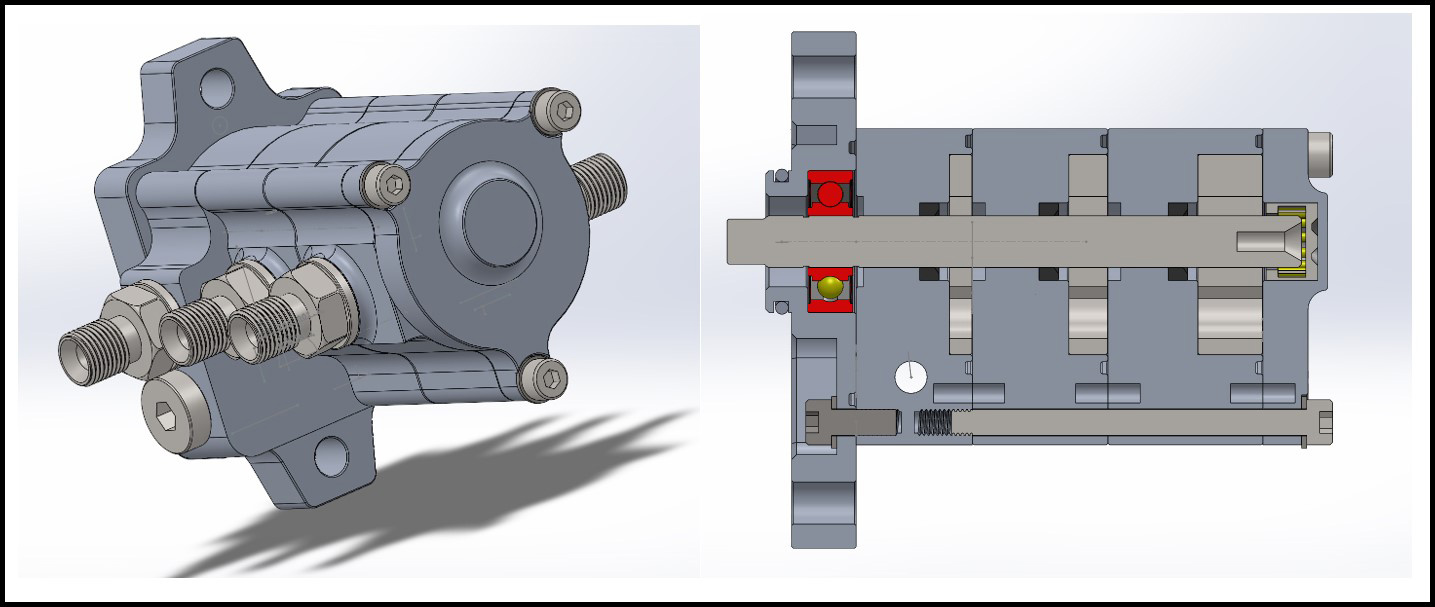

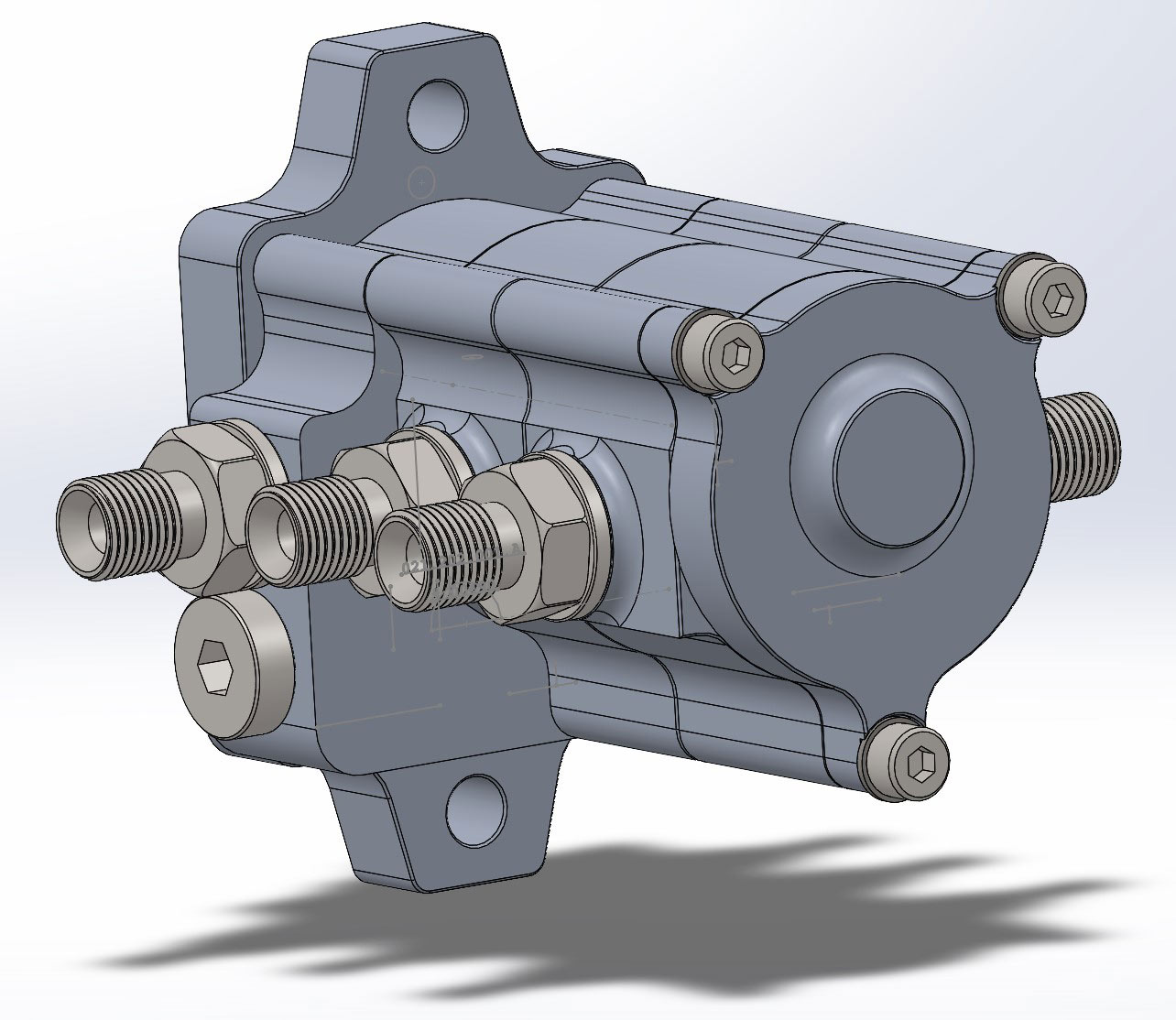

Complete Pump Assemblies

Complete pump assemblies including pressure relief valve systems, entry / exit connections, drive mechanism and housing sealing & fastener solutions.

30+ Years Experience

We have over 30 years experience in gerotor pump design and application, in the Automotive, Motorsport and Industrial sectors. Within the last 5 years we have also been involved with Medical, Nuclear, Oil & Gas, Aerospace and Marine.

Gerotor Only Designs

If you require help designing a bespoke gerotor, reverse engineering an existing set, or improving the performance of an existing pump, we can help. We can provide a number of options with detailed data, can guide you on DFM (Design For Manufacture) considerations and can help source a production supplier if required.

Complete Pump Design

Along with the gerotor design, we can also create complimentary porting and create relief valve systems if required. The interaction of these systems is critical to efficient pump performance.

Integration with Existing Systems

The pump should work within an entire system and consideration of that should be part of the design process. Suction head, delivery routing, pipework geometry and drive mechanisms are all important aspects which need careful consideration.

Reverse Engineering

Duplicating an obsolete gerotor is possible in a few easy steps. We have done this for vintage equipment and where the original supplier cannot be identified. It is also very useful in building simulation models of existing equipment where the gerotor details are not provided by the supplier.

Product Improvements

We have been very successful at creating gerotor profiles which increase the capacity of the pump without changing the housing dimensions (eccentricity, rotor diameter and thickness). 5-20% gains have been achieved, which can help a system suffering marginal pressure problems without the need for a complete new pump. Porting geometry can also help with efficiency, noise and friction.

Development Partners

Partnering with the major CAD providers enables our customers to generate accurate CAD models which can be used directly for manufacture. Our partnership with Gamma Technologies allows the gerotor profiles generated in GDS to be analysed at high fidelity and in combination with complete lubrication and/or mechanical systems. See our Development Partners page for more details.

Our Sectors

An oil pump on a large industrial machine suffered early life failures. Investigation led to a complete redesign to eliminate the failures and included additional improvements for ease of maintenance.

A design and manufacture project to combine three separate oil pumps (1x pressure; 2 x scavenge) into one assembly, saving 2x motors and considerable space. The mass of the combined pump had to be equal to the mass of one of the original pumps.

Initially a reverse engineering project, this gerotor set was redesigned to deliver 12% more capacity from the same package dimensions (diameter, thickness, eccentricity).