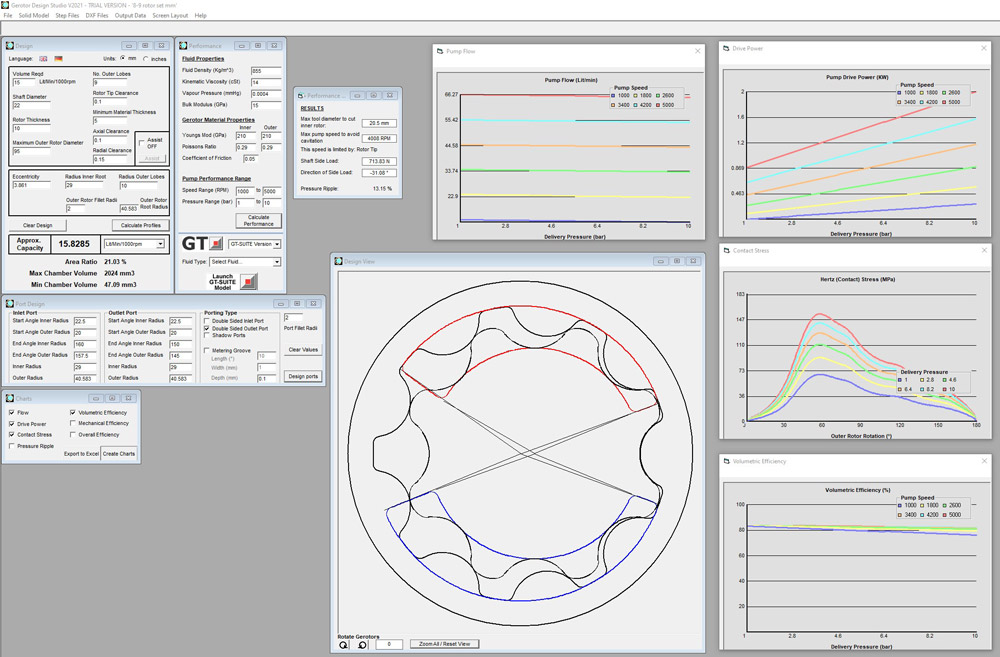

Profile Creation

Gerotor Profile creation in a few simple steps. Use the ‘Design Assist’ feature for bespoke designs, or enter measured data for reverse engineering.

Create porting designs and examine pump performance using the in-program analysis features.

Export

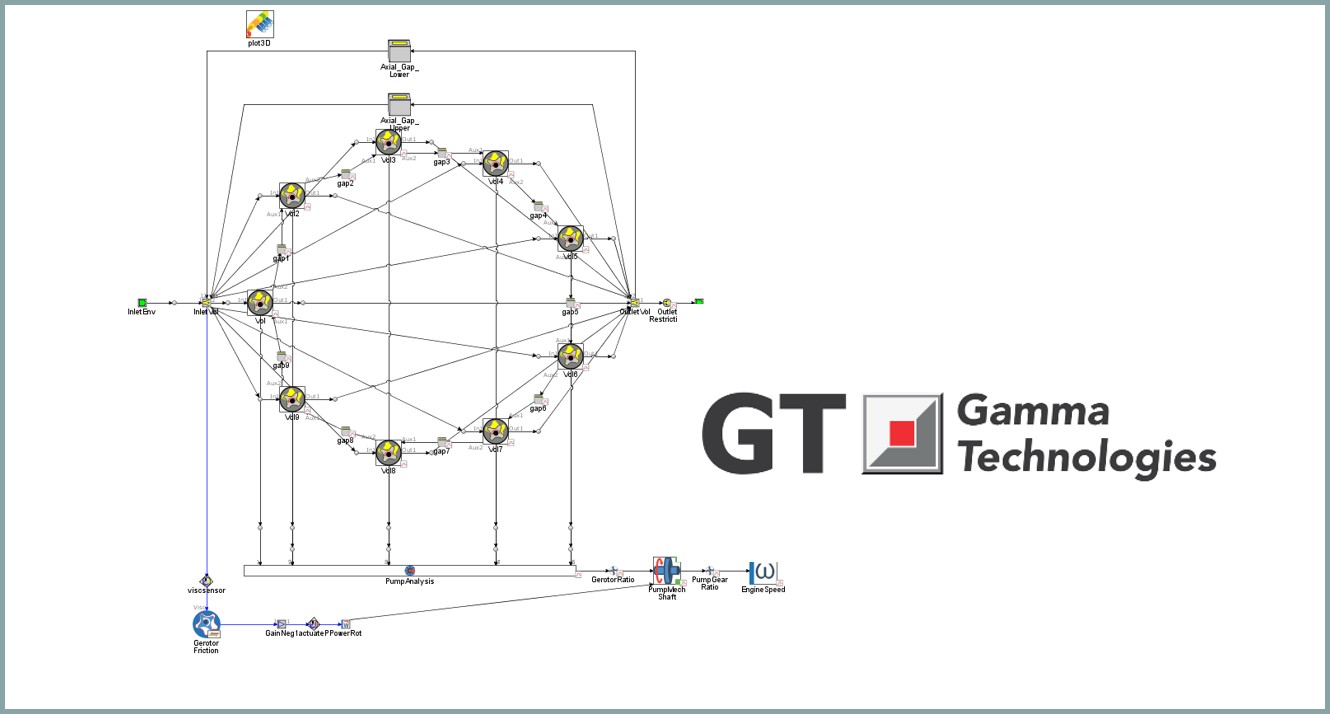

Export your pump model directly to GT-SUITE for extensive simulation and in-depth analysis using the World’s leading CAE tool.

Embed your pump model into larger system models for comprehensive system analysis.

Native CAD Models

Export native CAD models or create STEP models of Inner Rotor, Outer Rotor, Assembly and Porting Geometry for inclusion in pump assemblies or for use in CAM manufacturing systems.

Design New Gerotor Profiles

Easily create Gerotor designs by specifying all required inputs or use the intuitive ‘Design Assistant’ feature & in-program guidance to help you!

See your Gerotor profile instantly on screen – zoom & rotate functions available for closer examinations.

Reverse Engineer Gerotor Profiles

Enter the measured parameters from an existing set of gerotors to generate the profile, for reverse engineering or improvement studies.

Porting

With a gerotor design complete, the complimentary porting can be created automatically. Easily make further adjustments to suit the application if required. Add in Shadow Ports, Double Sided Ports and Metering Grooves to complete the porting geometry.

Performance Calculations

Enter some basic fluid properties and pump operating parameters and create a comprehensive set of performance data to help guide the design. View the data on screen or export it directly to Excel (numerical and Graphical data).

Analyse with GT-Suite

The GDS software builds GT-Suite gerotor models directly from the user interface! All parameters and inputs for the model are created with a single click. High fidelity simulations of the pump can be built and run, or embedded in larger system models. A license for GT-Suite is required to access this capability.

CAD Model Generation

3D models of the inner, outer, assembly rotors and porting can be created directly in either STEP format or native formats for the following packages: SOLIDWORKS, AutoDESK Inventor, AutoDESK AutoCAD, Siemens SolidEdge, Catia V5.

Manufacturing Data Output

Export manufacturing data (profile co-ordinates, tool offset co-ordinates, G-Code, etc.) directly from the user interface. This data can form the basis of a sub-routine for a CNC machining cycle. Create gerotor profiles and port profile data with this feature.