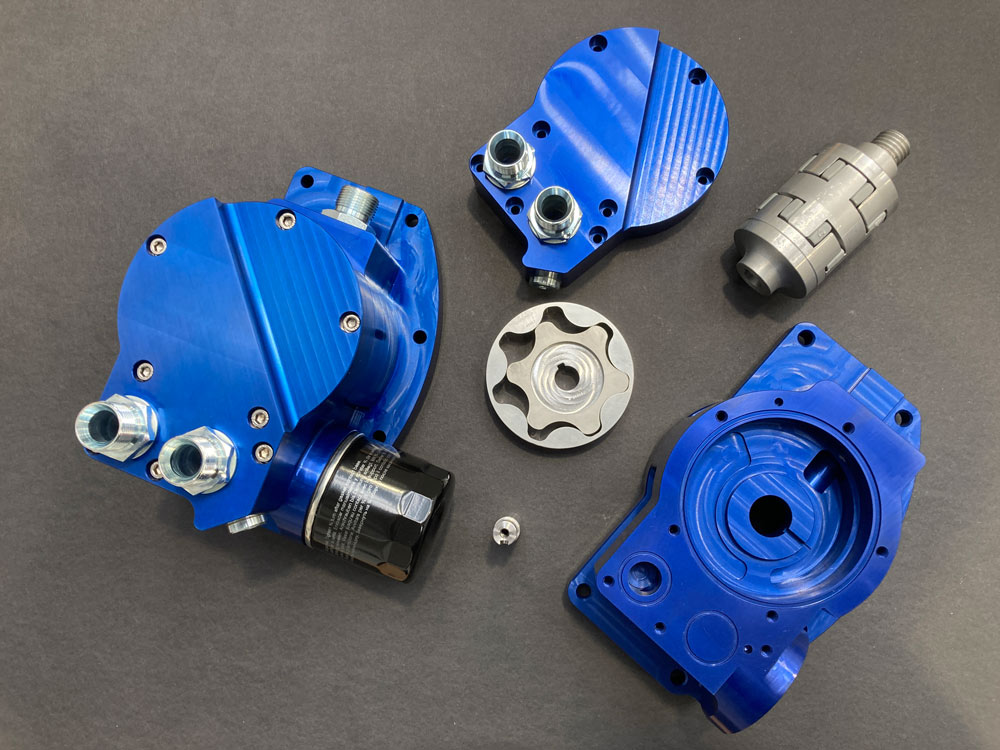

Seven Stage Oil Pump

A seven stage oil pump (2 x pressure; 5 x scavenge) for an aerospace project.

Gerotor design and manufacture of 3 sets of prototype parts.

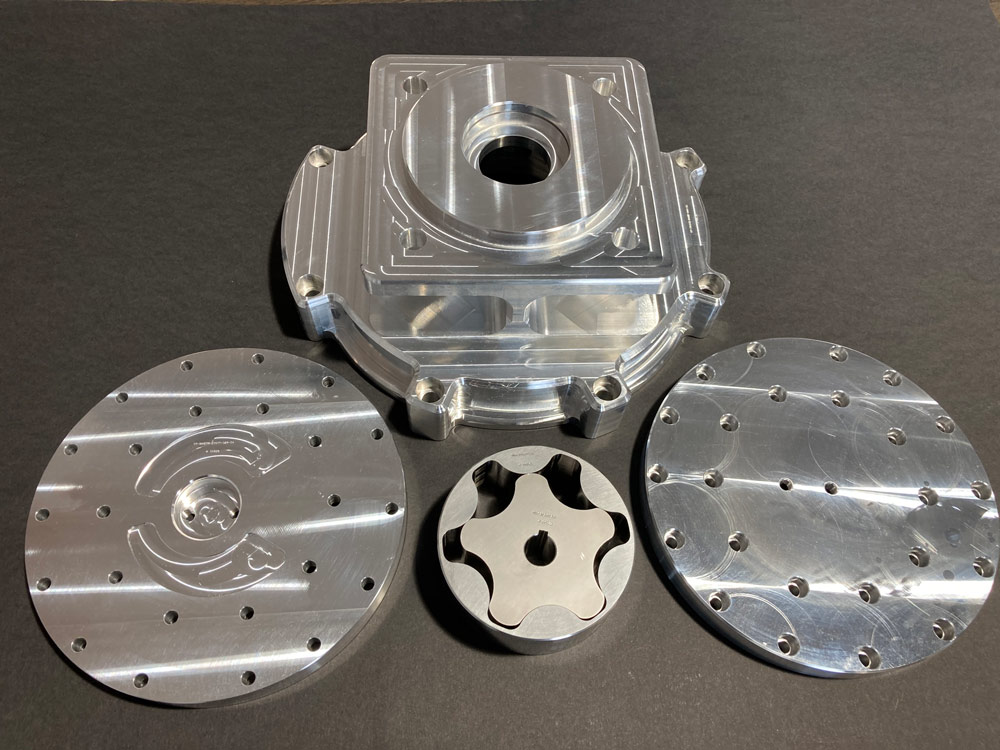

Lubricating Oil Pump

Large capacity lubricating oil pump for an industrial application.

Complete pump design and manufacture including housings, gerotors and drive mechanism.

Large Capacity Pump

Large capacity pump for use in hydraulic power-pack application.

Gerotor design and manufacture of 1 set of components.

Gerotors Only or Complete Pumps

We can manufacture however much or little of your pump project you need – from just the gerotor sets, up to complete pump assemblies including drive mechanisms and relief valve systems.

Manufacturing Capabilities

Our in-house machine shop has 4 axis CNC milling, CNC Y axis lathes with Live Tooling and standard lathe machines. We also have surface grinding capability and connections to sub-suppliers with excellent Wire EDM capabilities if needed.

Anodising / Coating

Most of our housings are anodised (either colour or hard) and we have accredited suppliers who help us with this. Anodising requires some additional inputs during manufacturing to ensure the finished sizes are within the drawing tolerances. We can also electro-coat components for the aerospace industries if required.

One-Off to 1000-Off

Prototype quantities can be a small as 1 off. We can also work to around 1000 units per year as ‘prototype’ for gerotor sets manufactured from solid. Quantities higher than this we would consider ‘series manufacturing’ and can of course be discussed if required.

Quality Standards / Inspection

We hold ISO 9001:2015 accreditation and count the quality of our manufactured parts as key to our success. All our manufactured components are probed / measured during machining to ensure they are correct to drawing prior to being released. All of this data is recorded automatically.

PPAP

We can supply measurement reports and PPAP documentation if required.

Made In Britain

All of our manufacturing and sub-contracting is conducted in the UK, using only companies that hold the relevant quality standards for their field. In this way we keep control of the processes and timing to ensure our customers receive quality parts on time.